High-Density Polyethylene (HDPE) Pipe for Trenchless Installations

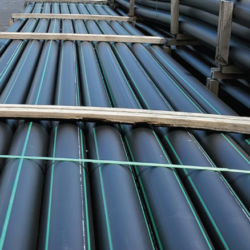

High-Density Polyethylene (HDPE) pipe remains the top choice for trenchless sewer and utility installations. Thanks to its strength, flexibility, and leak-free performance, HDPE is ideal for underground environments where long-term reliability matters.

Trenchless pipe bursting uses a steel cable to break apart your old sewer line while pulling in a new HDPE pipe at the same time. This process minimizes excavation and protects your landscaping, driveways, and hardscapes—saving time and reducing mess.

- Industrial pipe fitting and welding tools used by professional plumbers for precise pipeline connections.

Why HDPE Pipe Sets the Standard

HDPE delivers a rare combination of flexibility, chemical resistance, and structural strength. As a result, contractors frequently install it in residential, municipal, and industrial systems. It performs well in various soil types and harsh conditions.

According to the Plastics Pipe Institute, PE pipe has been widely trusted since the 1950s in both Europe and North America. It offers a proven record of leak-free service, long life, and corrosion resistance—all while keeping costs manageable over time.

Heat-Welded, Seamless Joints

Unlike traditional piping systems, HDPE sections are fused using heat-based methods like butt fusion, electrofusion, socket welding, or extrusion welding. These joints bond the pipe into a single continuous piece, often stronger than the pipe itself.

Because fusion eliminates mechanical fittings, adhesives, or rubber gaskets, the risk of root intrusion, joint separation, or internal corrosion drops significantly. This creates a truly watertight system, especially when compared to PVC or clay pipe alternatives.

Durability, Flexibility & Performance

HDPE performs exceptionally well in areas with unstable or shifting soil. On-site, it can flex to a radius 25 times its diameter (SDR11 or SDR17 below 20°C), which greatly reduces the need for elbows or added fittings.

Furthermore, HDPE’s smooth interior prevents buildup and resists friction loss. Unlike steel or cast iron, it won’t rust or corrode—ensuring strong flow rates and minimal maintenance for decades to come.

Safe for Drinking Water & Harsh Environments

Since we use food-grade virgin polyethylene, HDPE pipe becomes safe for drinking water after flushing. Moreover, it resists acidic and corrosive fluids, making it ideal for process piping, gas systems, and industrial use.

Its low thermal conductivity helps maintain steady fluid temperatures. Therefore, you can often skip extra insulation, protective coatings, or galvanizing—reducing both installation complexity and long-term maintenance costs.

Need HDPE Installed?

At MCM Plumbing, we specialize in trenchless installations using high-quality HDPE pipe. Whether you’re upgrading your sewer lateral or managing a larger utility project, our licensed team can help. Contact us today for a free consultation or to request a detailed quote.

View Terms & Conditions & Service Disclaimers

Trademark Notice: MCM Plumbing™ is a trademark owned by MCM Plumbing. You need written permission to use our name, logo, or likeness.